Lathe Work Area & Tool Storage (2006)

Here's the lathe work area. I'm lucky enough to have a Powermatic 3520b lathe, and its a fantastic machine. Notice the tool rack to the left of the lathe. I love having all the tools close to the lathe, and it's great to have them positioned so that I'm not reaching over the spinning workpiece to grab a new tool - much safer than my previous setup.

It's great to have everything close at hand and well orgainized.

Update 11/22/06:

Just thought it would be cool to show a pic of the lathe semi-buried in shavings after roughing out a few medium sized bowls and doing a bunch of spindle work. This stuff is a blast:

And here's a picture of a set of go-no go gages I made for sizing tenons and recesses with my various chuck jaws. This is much easier than finding the sizes in the manuals and setting up calipers. With these I can just grab a gage for the appropriate jaws and make sure the green fits and red doesn't. That ensures the tenon or recess will fit into the jaws correctly.

All they are are scrap pieces of

1/4" plywood with cutouts for the jaw ranges. I outlined the

tenon/recess that should fit in green and the one the should not in

red. Handy little buggers!

Update 1/23/07:

I've seen a few recent questions on line about how people handle dust collection and lighting on their lathe, so I snapped a few quick pics of my setup.

Update 1/23/07:

I've seen a few recent questions on line about how people handle dust collection and lighting on their lathe, so I snapped a few quick pics of my setup.

These first pics show the

articulating desk lamp that I attached to the arm that is designed for

the safety cage. I turned a dowel to fit into the thru-hole in

the casting and drilled a hole in the dowel to accept the stock

attachment hardware for the lamp. Works great, and since it's

attached to the headstock it moves with it and is always where it's

needed.

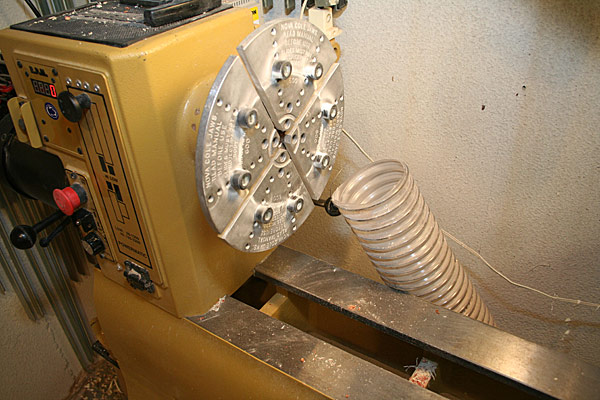

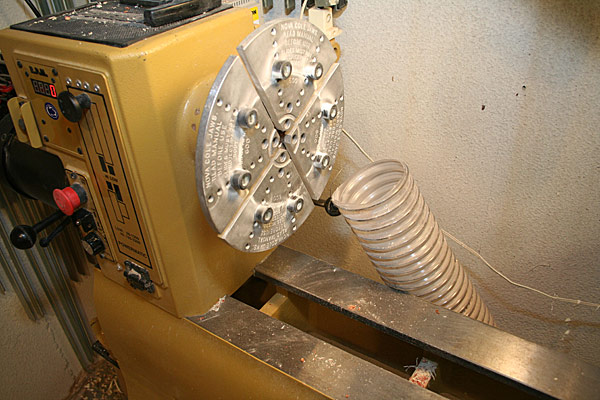

The next few pics show how I

handle dust collection for sanding and buffing. I simply insert a

rare earth magnet into the end of a flexible dc hose, and the magnet

holds the hose right to the bed of the lathe. By positioning the

magnet deeper into the hose I can have it stick up more (or less if the

magnet is shallower in the hose) from the lathe bed. The magnet

holds very securely, is very cheap, and is easy to move anywhere on the

lathe.

© Copyright 2006 Chris Billman